Why Thysse

Passion, Pride & Craftsmanship:

Delivering Exceptional Results. Every time.

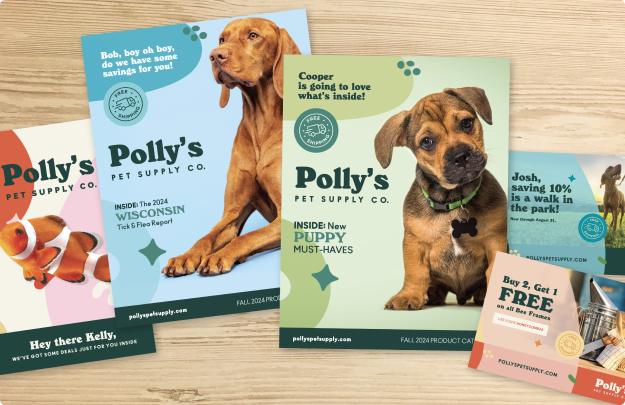

Thysse (tie • see) is a third-generation, family-owned commercial printer and brand experience provider. Just 15 minutes south of Madison, our state-of-the-art facility is located in Oregon, WI. Team Thysse is composed of over 100 individuals who help deliver exceptional service and project outcomes to some of the most valuable brands in the nation. Founded in 1941, Thysse has a long, proud history of innovating and investing in leading edge technologies. Our culture of thoughtful, solutions-oriented communicators allows us to stay at the forefront of what's possible in a commercial print partner.

Alex Pierce